Action B1 - Design and installation of prototypes

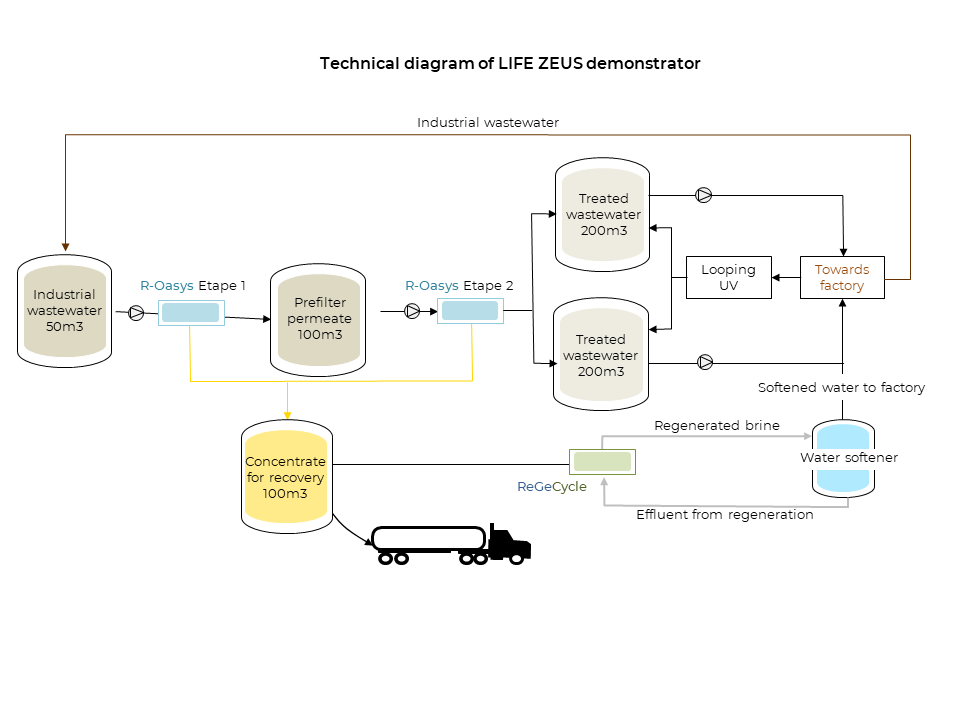

The action consists of building the two industrial prototypes in the CHEMDOC workshops in Clermont l'Hérault, then installing and commissioning them in the MONIN factory in Bourges.

This project covers all the stages involved in managing a design/build project for industrial equipment, including design studies, construction, intermediate acceptance in the workshop, regulatory inspections, on-site connection and commissioning. They are linked to and run in parallel with actions B2 and B3.

3 sub-actions :

Design and production studies, manufacture and testing of equipment in the workshop

Installation and commissioning of the ReGeCycle® prototype

Installation and commissioning of the R-Oasys® prototype

Action B.2 - Design and modification of demonstration site facilities

The action takes place on the MONIN site and on the OiEau premises.

It consists of putting in place the tools and skills to ensure the health safety and reliability of the demonstrator in order to control risks, manage by-passes in the event of non-compliance and define the limits of the system. A tool for monitoring, collecting and displaying data from the continuous sensors and analyses carried out by a specially created laboratory will also be created.

It comprises two sub-actions which will take place at the MONIN demonstration site in Bourges, in parallel with actions B1 and B3.

Modification of the demonstration site infrastructure

Modifications to the MONIN process: creation of loops and double networks

Action B3

The action takes place on the MONIN site and on the OiEau premises.

It consists of putting in place the tools and skills to ensure the health safety and reliability of the demonstrator in order to control risks, manage by-passes in the event of non-compliance and define the limits of the system. A tool for monitoring, collecting and displaying data from the continuous sensors and analyses carried out by a specially created laboratory will also be created.

B3 does not take into account the sensors integrated into the prototypes (action B1), which are part of the specific needs of each of them to control their operation (pressure probes, conductivity, dilution of washing product, etc.).

Given the work required to carry out qualitative monitoring, B3 will also include the quantitative aspects of measuring environmental impact, taking into account the results of action A1 to produce the data required for action C1.

To guarantee the safety of reused water, all stages of its production must be monitored: water resource, storage before treatment, treatment, storage before reuse and distribution.

In order to make the most of them, it is necessary to characterise the co-products.

3 sub-actions:

Definition of the water and co-product quality parameters, the monitoring scheme and selection of the sensors to be used.

Creation of a MONIN on-site laboratory and training of laboratory technicians

Development of a tool for collecting and displaying monitoring data for all flows.

Action B4 - Qualification goes Qualifying prototypes and the demonstrator and getting the demons

Qualification goes beyond the notion of commissioning prototypes, and more broadly encompasses validation of the design, the installation created, its operation and its performance, for the entire Networks - Plant - Prototypes assembly that makes up the demonstrator. In addition to the technical aspects, MONIN and OiEau will ensure that the organisation, procedures and staff training are adapted to maintain constant qualitative and quantitative performance.

The action will enable the demonstrator and the ReGeCycle® and R-Oasys® prototypes to be fully integrated into the protocols, organisation and documentary system of the demonstration site.

It will be carried out on the demonstration site as soon as phases B1, B2 and B3 have enabled the prototypes and the entire monitored demonstrator to be commissioned, so that qualification of the installation can be envisaged, followed by action B5. The INSA analyses for which MONIN will not be equipped (HPLC sugars, anions, cations) will be carried out in Toulouse.

B4 will consist of a more thorough commissioning of the entire demonstrator with the gradual reinjection of treated wastewater and co-products into the MONIN process:

ReGeCycle®, which processes fewer volumes and is technically less sensitive in terms of food safety, will be qualified first. The regenerated brine will first be discharged and then gradually re-injected into the softeners once they have been qualified until they are operating at full capacity.

R-Oasys®, which is more sensitive, will be treated second using the same approach, but with more detailed monitoring protocols and analyses.

The two methanisation plants, the ARS and the DDCSPP will be particularly involved in this start-up phase. The former will be directly involved in processing the co-product, while the latter will be involved as experts with whom the results will be shared.

Action B5 - Ongoing operation of the demonstrator

Action B5 consists of putting in place the organisation and resources to operate the LIFE ZEUS demonstrator and prototypes on a continuous basis.

The routine implementation of all the procedures, control and monitoring plans, and preventive and corrective maintenance will have been defined upstream of the LIFE ZEUS project and during actions B1, B2, B3 and especially B4. All processes will be clearly defined and formalised. The MONIN staff required for day-to-day monitoring will be identified and trained internally, in addition to the previous training courses (action B3).

Action B5 is essential for validating the environmental impact targeted, validating staff training, the technical configuration and the process in general, taking into account and analysing ageing factors.

Action B6 - Replicability and transferability of the ZEUS process

The aim of Action B6 is to refine and implement the ZEUS replication and transfer strategy.

B6 will maximise the impact of the project through replication and transfer. A market study will refine the marketing strategy with the support of a specialist consultancy or business school. It will quantify the market, its access routes, trends, players and competitors.

Industrial trials (on a scale of around 1 to 3 m3/d), carried out directly on potential sites, will complement the diagnostic tools developed in action B7 and tested during this action.

Potential customers will be approached directly.

To industrialise the ZEUS solution, a standardised range will be developed to reduce the cost and price of installations, based on the results of the market study.

Action B7 - Development of tools for replicating REUSE projects

B7 will facilitate the replication of the ZEUS solution in the agri-food sector by providing a technical and environmental assessment methodology and training modules for professional project leaders.

OiEau will develop an enriched, interactive and educational book, with the techniques to be favoured (B2), the instrumentation required (B3), the skills required (B3) and the methodology developed in D3 to support the transferability of the LIFE ZEUS solution to other agri-food industrialists.